Have you ever wondered what happens the moment you turn the key in a diesel vehicle? Unlike gasoline engines that rely on spark plugs to ignite fuel, diesel engines use a different, fascinating process to get going.

Understanding how diesel engines start can give you a new appreciation for the power and efficiency packed under the hood of your truck or car. You’ll discover the simple yet clever mechanics behind diesel ignition, why cold starts can be tricky, and how components like glow plugs play a crucial role.

Keep reading to unlock the secrets of diesel engine starting and see why this technology keeps delivering strong performance day after day.

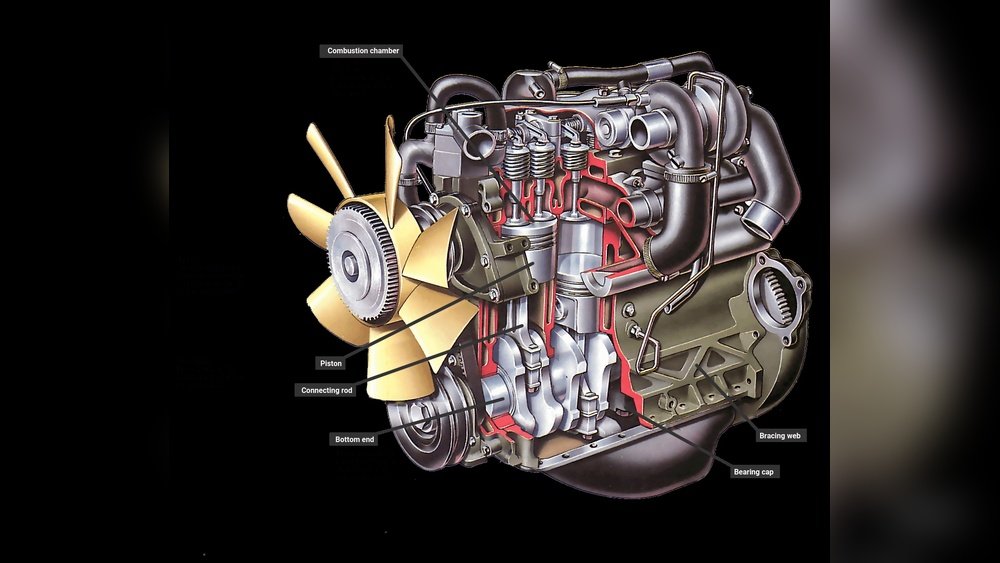

Diesel Engine Basics

Diesel engines are powerful machines that work differently from petrol engines. Their design allows them to run efficiently using a special process. Understanding these basics helps explain how diesel engines start and run smoothly.

They rely on a unique method to ignite fuel without needing spark plugs. This process gives diesel engines their strength and fuel efficiency, making them popular in many vehicles and machines.

Compression-ignition Principle

Diesel engines use the compression-ignition principle to start and run. Air is first drawn into the cylinder and compressed by the piston. This compression raises the air temperature to a very high level.

Once the air is hot enough, diesel fuel is injected into the cylinder. The fuel ignites immediately due to the high temperature, causing combustion. This process powers the engine without any spark plugs.

Differences From Petrol Engines

Diesel engines differ from petrol engines in how they ignite fuel. Petrol engines use spark plugs to ignite a fuel-air mix. Diesel engines rely on heat from compressed air to ignite fuel.

Diesel engines also have higher compression ratios than petrol engines. This makes them more fuel-efficient and able to produce more torque. The absence of spark plugs means fewer ignition parts and often more durability.

Role Of Compression In Starting

The role of compression in starting a diesel engine is crucial. Unlike gasoline engines, diesel engines do not use spark plugs to ignite fuel. Instead, they rely on the heat generated by compressing air inside the cylinder. This process raises the air temperature enough to ignite the diesel fuel. The compression must be strong and quick to create the right conditions for combustion. Understanding this process helps explain why diesel engines are powerful and efficient.

Air Heating Through Compression

When the piston moves up, it compresses the air inside the cylinder. This compression reduces the air volume drastically. As air compresses, its temperature rises sharply. The air can reach temperatures over 500 degrees Celsius. This high temperature is essential to ignite the diesel fuel. Without sufficient compression, the air would stay too cool to cause ignition.

Achieving Ignition Temperature

The ignition temperature is the point where diesel fuel catches fire. The compressed air must reach this temperature before fuel injection. Once the fuel sprays into the hot air, it ignites immediately. This ignition starts the engine’s power cycle. If the air is not hot enough, the engine struggles or fails to start. That is why compression quality and timing are vital for diesel engines.

Starter Motor Function

The starter motor is essential in starting a diesel engine. It provides the initial force needed to turn the engine’s crankshaft. This action begins the engine’s internal processes. Without the starter motor, the engine cannot start running on its own.

The motor is powered by the vehicle’s battery. When you turn the ignition key, electricity flows to the starter motor. The motor then engages with the engine’s flywheel to crank the engine. This process prepares the engine to start the compression cycle.

Cranking The Engine

The starter motor turns the engine’s crankshaft at a slow speed. This movement is called cranking. Cranking allows the engine’s pistons to move up and down inside the cylinders. This motion is needed to compress the air inside the cylinders.

During cranking, the starter motor must provide enough torque to overcome engine resistance. The motor keeps turning the crankshaft until the engine fires up. Once the engine starts running, the starter motor disengages automatically.

Initiating The Compression Cycle

Diesel engines rely on compression to ignite fuel. The starter motor’s cranking action begins this compression cycle. As the pistons move, they compress air inside the cylinders. This compression raises the air temperature significantly.

When the air is hot enough, diesel fuel injected into the cylinder ignites. This process powers the engine without spark plugs. The starter motor’s role ends after the engine starts running on its own power.

Glow Plugs And Cold Starts

Diesel engines rely on a unique starting process, especially in cold weather. Cold starts are challenging because diesel fuel needs high heat to ignite. Glow plugs play a key role in warming the engine for a smooth start. They help reach the necessary temperature quickly. This section explains how glow plugs assist diesel engines during cold starts.

Purpose Of Glow Plugs

Glow plugs heat the air in the combustion chamber before starting. They raise the temperature to ignite diesel fuel easily. Without glow plugs, cold air lowers the chance of ignition. These plugs are small but vital parts for cold weather. They ensure the engine starts faster and runs smoothly.

Starting Without Glow Plugs

Diesel engines can start without glow plugs in warm conditions. The engine cranks longer to build enough heat from compression. This process takes more time and effort from the starter motor. Cold weather makes starting without glow plugs very difficult. The fuel might not ignite, causing the engine to stall.

Glow Plug Operation Time

Glow plugs need a short time to warm up before starting. Usually, this takes between 5 to 30 seconds. Modern vehicles show a glow plug light on the dashboard. This light turns off when the plugs reach the right temperature. Using glow plugs only as long as needed saves battery power and reduces wear.

Fuel Injection Timing

Fuel injection timing plays a critical role in starting a diesel engine. It controls the exact moment diesel fuel enters the combustion chamber. Precise timing ensures the fuel ignites efficiently. This process affects engine power, emissions, and fuel economy.

Diesel engines rely on high compression to ignite fuel without spark plugs. Injecting fuel too early or late can cause rough starts or engine damage. Modern diesel engines use advanced systems to control injection timing accurately. These systems adapt to engine conditions for smooth starting and running.

Injecting Diesel At Peak Compression

The best moment to inject diesel is at peak compression. At this point, the air inside the cylinder is hottest and most compressed. Injecting fuel here allows it to ignite instantly. This timing maximizes combustion efficiency and engine power.

Injecting fuel too early causes poor combustion and engine knocking. Injecting too late results in incomplete burning and higher emissions. The fuel injection system must synchronize precisely with piston movement to hit peak compression.

Fuel Atomization And Mixing

Fuel injection timing also affects how well diesel mixes with compressed air. Diesel must atomize into tiny droplets to burn fully. The injector sprays fuel in a fine mist for better mixing.

Good atomization improves combustion speed and reduces smoke. Proper timing ensures fuel meets hot air at the right moment. This leads to cleaner and more powerful engine starts. Poor mixing causes rough running and wasted fuel.

Credit: mancinellis.com

Ignition Process Dynamics

The ignition process dynamics in diesel engines differ greatly from gasoline engines. Diesel engines rely on heat created by air compression to ignite fuel. This process requires precise conditions inside the engine cylinder. Understanding these dynamics helps explain how diesel engines start smoothly.

The ignition starts as the piston compresses air inside the cylinder. This compression raises the air temperature significantly. Fuel is then injected into this hot air, causing it to ignite without a spark. The entire process happens quickly and efficiently.

Auto-ignition Of Diesel

Diesel fuel ignites automatically due to high temperature from compression. The air inside the cylinder reaches temperatures above 500°C (932°F). At this heat level, diesel fuel vaporizes and ignites immediately upon injection. This is called auto-ignition.

No spark plugs are needed in a diesel engine. The heat from compressed air starts the combustion. This method is called compression ignition and is key to diesel engine operation.

Combustion Chamber Conditions

The combustion chamber must be very hot and under high pressure. The piston compresses air to about 20 to 25 times its original pressure. This raises the air temperature enough to ignite diesel fuel.

Fuel injectors spray a fine mist of diesel into the hot air. This ensures quick and complete combustion. The design of the chamber helps mix air and fuel efficiently. Good combustion chamber conditions lead to better engine performance and lower emissions.

Challenges In Cold Weather

Starting diesel engines in cold weather presents unique challenges. Low temperatures affect how the engine parts perform and how fuel behaves. The air inside the engine does not heat up enough during compression. This makes it hard for the fuel to ignite and start the engine. Cold weather can cause longer starting times and more wear on engine parts. Special methods help overcome these cold weather difficulties.

Low Temperature Effects

Cold air is denser and holds less heat. When compressed in the engine, it does not reach the needed temperature to ignite diesel fuel. Diesel fuel also thickens and flows poorly in low temperatures. This slows fuel injection and affects combustion. Engine oil becomes thicker, making engine parts harder to move. Batteries lose power in cold weather, reducing starter motor strength. All these factors combine to make starting diesel engines tough in cold conditions.

Engine Block And Fuel Heating Solutions

Heating the engine block helps keep engine parts warm. This reduces oil thickness and helps the engine turn easily. Engine block heaters plug into a power source to provide gentle warmth. Fuel heaters warm diesel fuel to improve flow and combustion. Glow plugs heat the air in the combustion chamber, raising temperature for ignition. Some diesel vehicles use intake air heaters to warm air before compression. These solutions improve starting reliability and reduce engine wear in cold weather.

Credit: www.holtsauto.com

Modern Innovations

Modern diesel engines use new technology to start faster and more reliably. These engines work well even in cold weather. Engineers have improved parts to help the engine reach the right temperature quickly. This makes starting easier and reduces wear on the engine. The innovations also help lower emissions and save fuel.

Advanced Glow Plug Technologies

Glow plugs heat the air in the engine cylinder before starting. Modern glow plugs heat up faster than older ones. Some use ceramic materials for better heat and durability. They reach high temperatures in just a few seconds. This quick heating helps diesel ignite even in cold conditions. New glow plugs also use less power from the battery.

Electronic Control Of Start Sequence

Modern diesel engines use computers to control the start process. The electronic control unit (ECU) manages glow plug heating and fuel injection timing. It adjusts the start sequence based on engine temperature and other data. This control ensures smoother starts and reduces engine strain. The ECU also helps reduce emissions during cold starts. This technology improves overall engine performance and reliability.

Credit: atldiesel.com

Conclusion

Diesel engines start by compressing air to high temperatures. This heat ignites the diesel fuel without spark plugs. Glow plugs help start the engine in cold weather. The starter motor turns the engine until it runs on its own. Understanding this process shows how diesel engines work efficiently.

It also explains why they differ from gasoline engines. Diesel engines rely on heat, not sparks, to begin running. This simple yet powerful method keeps them reliable and strong.