If you’ve ever wondered how to get the most out of your air compressor, you’re in the right place. Whether you want to inflate tires, power nail guns, or tackle DIY projects, knowing how to use an air compressor correctly can save you time and effort.

In this guide, you’ll learn simple, step-by-step tips to safely operate your compressor and get the job done right. Ready to unlock the full potential of your tool? Keep reading, and you’ll be surprised at how easy it is to master your air compressor.

Air Compressor Basics

An air compressor is a powerful tool that converts power into potential energy stored in pressurized air. Understanding its basics helps you use it safely and effectively. This section explains how air compressors work, the types available, and their common uses.

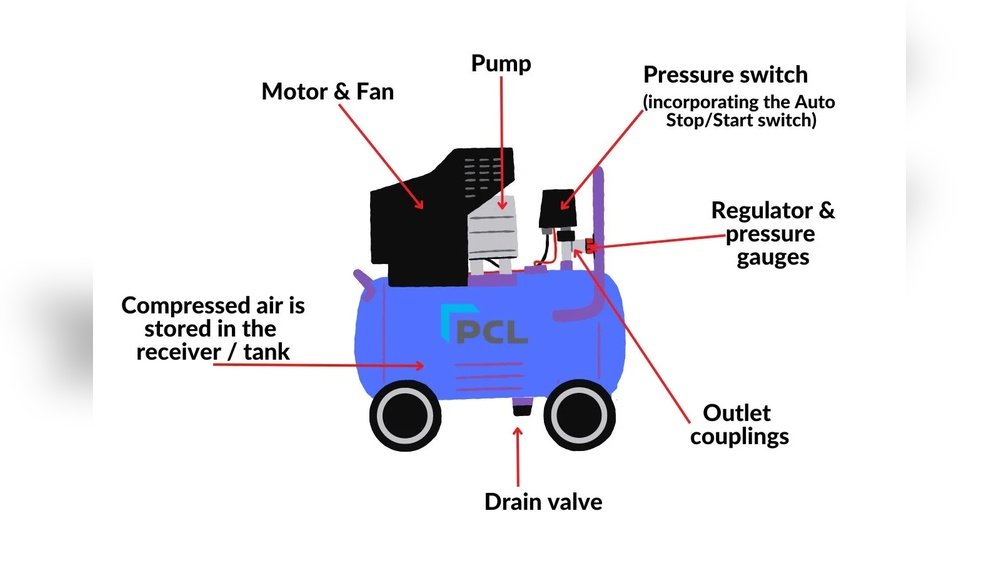

How Air Compressors Work

An air compressor pulls in air and squeezes it into a smaller space. This process increases the air pressure inside a tank. The compressed air stays stored until needed. When turned on, the compressor pushes air out with force. This air can power tools or inflate tires.

Types Of Air Compressors

There are two main types: piston and rotary screw compressors. Piston compressors use a piston inside a cylinder to compress air. They are common for home and small workshop use. Rotary screw compressors use two screws that turn to compress air. They are often used in large industrial settings. Some compressors are portable, while others are fixed in place.

Common Uses

Air compressors serve many purposes. They inflate tires, sports equipment, and air mattresses. They power nail guns, spray painters, and impact wrenches. In workshops, they clean surfaces and operate machinery. Compressed air also helps in construction, automotive repair, and home DIY projects.

Credit: www.youtube.com

Choosing The Right Compressor

Choosing the right air compressor is essential for effective and safe work. The correct compressor matches the task you want to do. It saves time, energy, and money. This section guides you through key points to consider before buying or using an air compressor.

Matching Compressor Size To Tasks

Air compressors come in different sizes. Small compressors work well for inflating tires or blowing dust. Larger compressors handle more demanding jobs like spray painting or running power tools. Check the air volume (CFM) and pressure (PSI) needed for your task. Pick a compressor that meets or exceeds these needs.

Power Source Options

Compressors run on electricity, gas, or battery power. Electric models suit indoor use with easy access to outlets. Gas-powered compressors offer more mobility for outdoor jobs but need fuel and maintenance. Battery compressors are lightweight and quiet but may have limited run time. Choose based on where and how you will work.

Portability Considerations

Think about where you will use the compressor. Portable compressors are light and often have handles or wheels. They fit well in small workshops or on job sites. Stationary compressors are heavier and stay in one place. They provide higher air capacity but lack mobility. Pick the style that fits your workspace and job needs.

Setting Up Your Compressor

Setting up your air compressor correctly is essential for safe and efficient operation. Proper setup ensures your compressor works well and lasts longer. This section guides you through the basic steps needed before using your air compressor.

Selecting A Location

Choose a flat, stable surface to place your compressor. Avoid damp or dusty areas to protect the machine. Leave enough space around the compressor for airflow and maintenance. Keep it away from flammable materials to prevent fire hazards.

Checking The Drain Valve

Locate the drain valve at the bottom of the tank. Open it to remove any water or moisture that may have collected. Draining prevents rust inside the tank and keeps the compressor working efficiently. Do this regularly, especially after each use.

Power Requirements

Check the voltage and power needed for your compressor. Use the correct power outlet to avoid damage or electrical hazards. Make sure the power source can handle the compressor’s startup current. Avoid using extension cords unless they are rated for the compressor’s power.

Credit: www.youtube.com

Pressure Settings

Setting the correct pressure on an air compressor is essential for safe and effective use. Pressure settings control how much air flows out and affect the performance of your tools. Too much pressure can damage tools or cause injury. Too little pressure may not power the tool properly.

Understanding and adjusting pressure settings helps you get the best results. Follow simple steps to set pressure for different tasks. This guide explains pressure basics and how to adjust the regulator for specific tools.

General Pressure Guidelines

- Check the tool’s manual for the recommended pressure.

- Use the compressor’s pressure gauge to monitor PSI.

- Start with low pressure and increase as needed.

- Never exceed the maximum pressure rating of your tool.

- Keep pressure stable for consistent tool performance.

Adjusting The Regulator

- Locate the pressure regulator knob on your compressor.

- Turn the knob clockwise to increase pressure.

- Turn the knob counterclockwise to decrease pressure.

- Watch the output pressure gauge to set the right PSI.

- Test the tool briefly to confirm the pressure feels correct.

Pressure For Specific Tools

- Nail guns usually need 70 to 120 PSI for proper firing.

- Impact wrenches work well between 90 and 120 PSI.

- Paint sprayers require lower pressure, around 30 to 50 PSI.

- Blow guns use low pressure, often below 30 PSI.

- Check each tool’s manual for exact pressure recommendations.

Recommended Psi For Tires

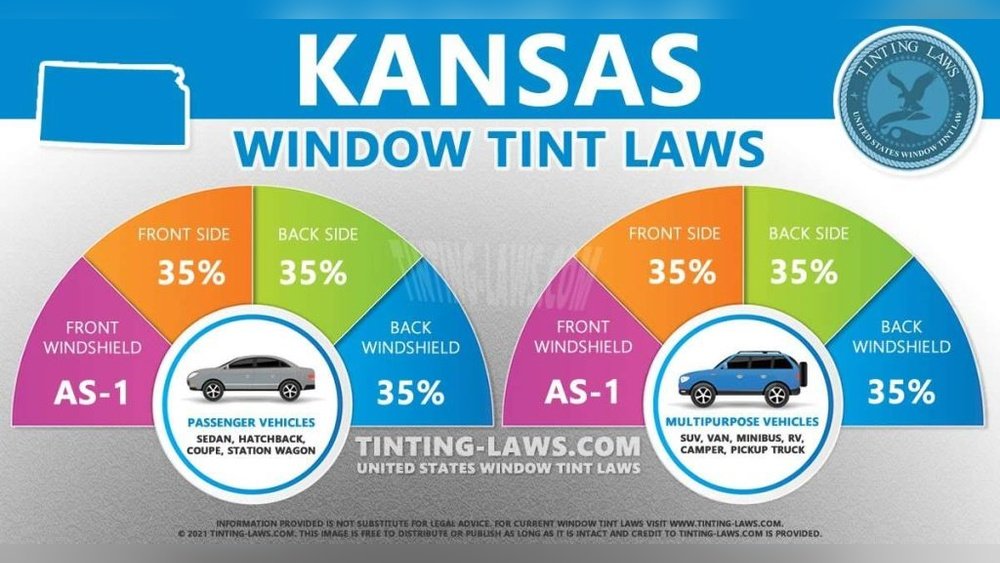

- Passenger car tires usually require 30 to 35 PSI.

- Light trucks may need 35 to 45 PSI.

- Check the tire sidewall or vehicle manual for exact PSI.

- Use the air compressor’s gauge to avoid overinflating.

- Stop inflating once the recommended pressure is reached.

Connecting Tools And Accessories

Connecting tools and accessories to an air compressor is a key step for smooth operation. Proper connections ensure air flows efficiently and safely. This section explains how to attach tools and accessories correctly.

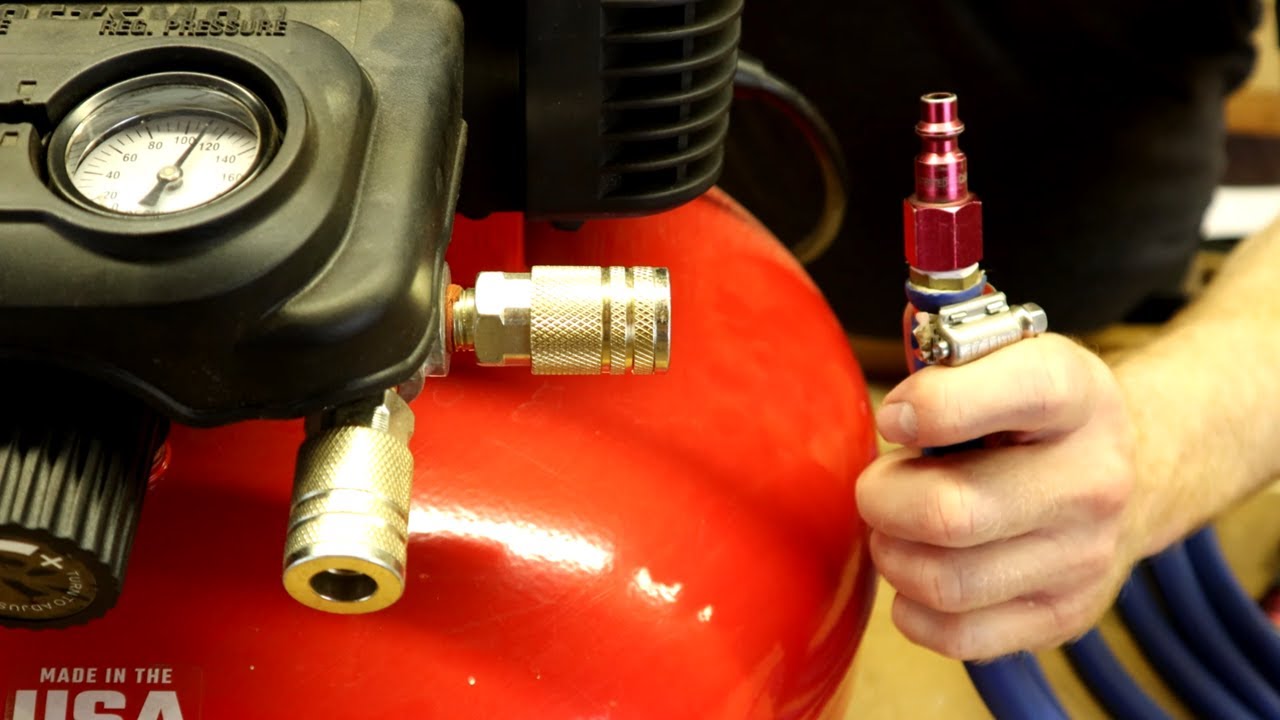

Using Quick-connect Couplers

Quick-connect couplers make attaching tools fast and easy. Push the coupler into the compressor’s air outlet until it clicks. To release, pull back on the sleeve and remove the tool. Use couplers that match your compressor’s size and type.

Hose Attachment Tips

Secure hoses tightly to prevent air leaks. Wrap tape around threads if using threaded connections. Avoid sharp bends or kinks in the hose to maintain airflow. Keep hoses away from heat and sharp objects for safety.

Tool Compatibility

Check if your tool works with the compressor’s pressure and airflow. Each tool has a recommended PSI and CFM rating. Using incompatible tools can cause poor performance or damage. Always read the tool manual before connecting it.

Operating The Compressor

Operating an air compressor involves careful steps to ensure safety and efficiency. Understanding how to start, monitor, and control the machine helps you get the best results. This section explains the basic actions to operate your air compressor correctly.

Starting And Stopping

Begin by checking the oil and air filters if your compressor needs them. Connect the power source and turn on the main switch. The motor will start pumping air into the tank.

To stop, turn off the switch and unplug the compressor. Wait for the pressure to release before disconnecting any hoses or tools.

Monitoring Pressure Gauges

Look at the pressure gauges to see the air pressure inside the tank. The gauges help prevent overpressure, which can cause damage. Keep the pressure within the recommended range for your tool.

Check the gauges regularly during use. If the pressure is too high or low, adjust the regulator to maintain safe operation.

Controlling Air Flow

Use the regulator knob to adjust how much air flows to your tool. Turning it one way increases pressure, the other way decreases it. Setting the correct air flow improves tool performance and safety.

Always match the air flow to the tool’s needs. Too much air can damage the tool, and too little can reduce its power.

Inflating Tires With An Air Compressor

Inflating tires with an air compressor is quick and simple. It keeps your tires at the right pressure for safe driving. Using an air compressor also saves trips to the gas station. Follow easy steps to do it correctly and avoid mistakes.

Attaching The Chuck

First, remove the valve cap from the tire. Take the air compressor hose and press the chuck firmly onto the valve stem. Push until you hear air flow or feel a tight fit. Hold it steady to keep a good connection.

Avoiding Air Leaks

Check for any hissing sounds near the chuck. Hissing means air is escaping. Adjust the chuck or press it harder to stop leaks. A tight seal helps the tire fill faster and keeps the compressor running smoothly.

Checking Tire Pressure

Use a tire pressure gauge to check the pressure after inflating. Compare it to the recommended PSI on your tire’s sidewall or car manual. Add air in small bursts and check often. Stop when the pressure matches the recommended level.

Maintenance And Care

Proper maintenance and care keep an air compressor working well and extend its life. Regular attention prevents breakdowns and ensures safety during use. Small steps taken after every use make a big difference over time.

Draining Moisture

Air compressors collect moisture inside the tank. This happens because air contains water vapor. Draining the tank removes this moisture. Open the drain valve at the tank bottom to let water out. Do this after each use. Moisture can cause rust and damage the tank if left inside.

Cleaning And Inspection

Keep the compressor clean by wiping dust and dirt off. Check air filters regularly. Clean or replace them to keep airflow steady. Look for leaks or loose parts. Tighten screws and bolts as needed. Inspect hoses for cracks or damage. Fix or replace damaged parts right away.

Storing The Compressor

Store the air compressor in a dry, cool place. Avoid humid or wet areas to prevent rust. Coil hoses neatly without kinks. Cover the compressor to protect it from dust. Make sure it is off and unplugged before storing. Proper storage keeps it ready for the next use.

Safety Tips

Safety is the top priority when using an air compressor. The machine works with high pressure air that can cause injuries if not handled properly. Following safety tips protects you and others around you. It also keeps the air compressor in good working condition for a long time.

Proper Use Of Ppe

Always wear personal protective equipment (PPE) before starting the air compressor. Safety glasses protect your eyes from flying debris. Ear protection reduces noise damage from the compressor. Gloves help you grip tools and prevent hand injuries. Wear sturdy shoes to protect your feet from heavy objects.

Avoiding Over-pressurization

Check the pressure gauge regularly to avoid over-pressurization. Set the regulator to match the tool’s recommended PSI. Never exceed the maximum pressure limit of the tank. Over-pressurization can cause the tank to burst or damage tools. Release pressure slowly when finished to prevent sudden air bursts.

Handling Emergency Shutdowns

Know the location of the emergency shutoff valve. Turn off the compressor immediately if you hear strange noises or see leaks. Disconnect the power supply before inspecting any issues. Keep the area clear of people during shutdown. Report any problems to a qualified technician for repair.

Credit: www.bigrentz.com

Frequently Asked Questions

How To Use An Air Compressor To Inflate Tires?

Connect the air compressor hose to the tire valve stem. Press the chuck firmly until air flows. Monitor the tire pressure gauge. Stop when reaching the recommended PSI. Remove the chuck carefully to avoid air leaks.

How Does An Air Compressor Work For Dummies?

An air compressor pulls in air, squeezes it to reduce volume, and stores it in a tank. When pressure hits the limit, it stops.

How To Correctly Use A Compressor?

Set the compressor on a flat surface and close the drain valve. Plug in and power on. Adjust threshold and ratio to control peaks. Fine-tune attack, release, and knee settings. Apply make-up gain, then review and adjust. Always test with A/B comparison for best results.

What Psi Should I Set My Air Compressor At?

Set your air compressor PSI based on the tool’s manual recommendations. Use the regulator to match required pressure. Avoid exceeding tool limits for safety and efficiency.

Conclusion

Using an air compressor safely and correctly makes tasks easier. Always read your tool’s manual before starting. Adjust the pressure to match your job needs. Keep the compressor clean and check it regularly. With practice, you will feel more confident handling it.

Remember, small steps lead to better results. Stay patient and work carefully every time. An air compressor is a useful tool when used right.