If you drive a 6.7 Powerstroke, you know how important the turbocharger is for keeping your truck running strong. But what if your turbo starts acting up?

You might notice your truck losing power, struggling to accelerate, or even spewing unusual smoke from the exhaust. These signs don’t just mean a rough ride—they could be warning you of a bad turbo that needs attention before it causes bigger damage.

You’ll learn the key signs to watch for, common causes behind turbo problems, and what steps you should take to protect your engine and keep your Powerstroke performing at its best. Don’t ignore these warning signals—your truck depends on it.

Power Loss And Sluggishness

Power loss and sluggishness are common signs of a failing turbo in a 6.7 Powerstroke engine. The turbocharger boosts engine power by pushing more air into the combustion chamber. When it fails, the engine struggles to perform well. This results in slower acceleration and weaker power delivery.

The truck may feel slow, especially under heavy load or during quick acceleration. This happens because the turbo is not producing enough boost pressure. Without proper boost, the engine burns less fuel and air, losing its strength.

Reduced Acceleration And Weak Performance

The engine takes longer to respond when pressing the gas pedal. You may notice the truck hesitates before speeding up. This lag is a sign of poor turbo function. The turbo’s inability to spin fast enough reduces airflow to the engine.

Visible Smoke From The Exhaust

Excessive black or blue smoke often appears with turbo issues. Black smoke means the engine is running rich due to poor air supply. Blue smoke shows oil leaks inside the turbo seals. This oil burns in the engine and creates blue smoke.

Engine Sounds Indicating Turbo Trouble

Listen for unusual noises like whining or grinding from the turbo area. A siren-like whine or whistle at idle may point to turbo wear. Grinding or scraping sounds during deceleration can mean damaged turbo bearings.

Higher Fuel Consumption

A failing turbo causes the engine to work harder and use more fuel. Poor combustion lowers fuel efficiency. You might notice you need to fill the tank more often than usual.

Excessive Exhaust Smoke

Excessive exhaust smoke is a common sign of turbo problems in the 6.7 Powerstroke. It shows the engine is not running cleanly. Different colors of smoke point to different issues. Noticing these colors can help diagnose the turbo’s condition quickly.

Black Smoke And Fuel Issues

Black smoke means too much fuel burns in the engine. This happens when the turbo cannot supply enough air. The engine tries to keep power by adding fuel, causing thick black smoke. Poor fuel atomization or clogged air filters can add to the problem. Black smoke also signals lower fuel efficiency and more pollution.

Blue And White Smoke From Oil Burning

Blue or white smoke means oil leaks into the combustion chamber. This happens if turbo seals are worn or damaged. Oil burns along with fuel, creating blue or white smoke. This smoke is often thin but has a strong smell. Burning oil can cause engine damage and loss of power. Watch for this smoke after turbo failure or oil leaks near the turbo.

Unusual Noises From Turbo

The turbocharger on a 6.7 Powerstroke plays a key role in engine power and efficiency. Unusual noises from the turbo often signal trouble. These sounds mean the turbo might be damaged or failing. Detecting these noises early helps prevent bigger engine problems and costly repairs.

Listen carefully to any strange sounds coming from the turbo. Different noises point to different issues inside the turbo system. Understanding these sounds helps you know what action to take next.

Whining And Whistling Sounds

A high-pitched whining or whistling noise often comes from a worn turbo bearing or a boost leak. This sound may grow louder as engine speed increases. It usually means the turbo is struggling to spin freely. The whistling can also indicate air escaping through a cracked hose or loose connection. Ignoring these noises can cause loss of power and further damage.

Grinding And Scraping Noises

Grinding or scraping sounds from the turbo are more serious. They often mean the turbo shaft or compressor wheel is damaged. This can happen if debris enters the turbo or if the bearings wear out. These noises may feel harsh and metallic, signaling internal contact between moving parts. Continuing to drive with these sounds risks complete turbo failure and expensive engine damage.

Credit: dieseliq.com

Reduced Fuel Economy

Reduced fuel economy is a common sign of a failing turbo on a 6.7 Powerstroke. The turbocharger helps the engine burn fuel more efficiently. When it starts to fail, the engine must work harder. This causes more fuel to be used than normal.

Fuel consumption rises noticeably during regular driving. You may find yourself filling up the tank more often. This drop in efficiency can affect your truck’s overall performance and running costs.

How A Bad Turbo Affects Fuel Economy

A failing turbo does not compress air properly. Less air means the engine cannot burn fuel fully. This incomplete combustion wastes fuel. The engine compensates by injecting more fuel to maintain power.

Signs Of Poor Fuel Efficiency In Your Powerstroke

You may notice a sudden drop in miles per gallon. The truck may feel sluggish or less responsive. Increased black smoke from the exhaust also signals poor fuel burn. These symptoms point to turbo issues harming fuel economy.

Why Fuel Economy Declines With Turbo Problems

Damaged turbo seals leak oil into the intake. This oil contaminates the air-fuel mix. The engine runs rich, using extra fuel to burn off the oil. Carbon buildup on turbo vanes further reduces efficiency.

Steps To Take When Fuel Economy Drops

Scan your truck for error codes related to the turbo. Have a trusted mechanic inspect the turbo system. Cleaning or replacing worn parts can restore proper function. Regular maintenance prevents long-term fuel economy loss.

Check Engine Light Alerts

The Check Engine Light (CEL) is a key warning sign for turbo issues in the 6.7 Powerstroke. This alert signals the engine computer has detected a problem. Ignoring the CEL can lead to severe damage and costly repairs.

The light may flash or stay solid, depending on the issue’s severity. A flashing CEL usually means a serious problem that needs immediate attention. A steady light indicates a less urgent but still important issue.

Understanding Cel Codes For Turbo Problems

When the CEL comes on, a diagnostic code is stored in the engine’s computer. These codes help identify if the turbo is causing the problem. Common codes related to the turbo include issues with boost pressure, turbo speed sensors, or exhaust gas recirculation.

Using an OBD-II scanner can reveal these codes quickly. Mechanics use these codes to pinpoint the exact turbo fault.

Common Turbo-related Cel Alerts

Look for codes indicating low boost pressure or boost leaks. These often mean the turbo isn’t spinning fast enough or there is a leak in the system. Another common code shows actuator failure, affecting the variable geometry turbo (VGT) vanes.

Turbo bearing failure or oil seal leaks also trigger CEL alerts. These issues reduce turbo efficiency and cause smoke or noise problems.

Immediate Actions After Cel Alerts

Stop driving if the CEL is flashing. Continuing may cause engine damage. If the light is steady, schedule a diagnostic check soon. Early detection prevents further turbo damage.

Have a qualified mechanic inspect the turbo system. They will check the turbo actuator, boost pressure, and oil seals to find the exact cause.

Oil Leaks And Burning Oil

Oil leaks and burning oil are common signs of a failing turbo in a 6.7 Powerstroke. These issues often indicate worn seals or internal damage. Spotting these early can prevent costly repairs and keep your engine running smoothly.

Oil leaks usually appear around the turbo housing or near the oil supply lines. Burning oil happens when oil seeps past damaged seals into the combustion chamber. Both problems reduce turbo efficiency and harm engine performance.

Oil Leaks Around The Turbo

Oil leaks near the turbo show as wet spots or drips on the turbo housing. These leaks can come from failed seals or cracked lines. Leaking oil can cause smoke and foul smells. It also lowers oil levels, risking engine damage.

Blue Or White Smoke From Exhaust

Burning oil produces blue or white smoke from the tailpipe. This smoke is a clear sign oil enters the combustion chamber. The problem usually stems from broken turbo seals or worn bearings. The smoke may increase with engine load or acceleration.

Oil Consumption Increase

If your 6.7 Powerstroke suddenly uses more oil, suspect turbo issues. Burning oil inside the turbo causes faster oil loss. You may need to add oil more often than usual. Ignoring this can cause engine wear and costly repairs.

Carbon Buildup Effects

Carbon buildup inside the turbo of a 6.7 Powerstroke causes serious problems. It clogs moving parts and reduces turbo efficiency. This buildup mainly occurs around the Variable Geometry Turbo (VGT) vanes. These vanes adjust boost pressure for better engine performance.

Carbon deposits limit the vanes’ movement. This leads to poor boost control and sluggish engine response. The engine may hesitate during acceleration or feel weak under heavy load. Carbon buildup also increases exhaust backpressure, hurting overall power.

Restricted Vgt Vane Movement

Carbon deposits cause VGT vanes to stick or move slowly. The vanes can’t adjust boost properly. This results in poor throttle response and loss of power. The engine may feel less responsive at low RPMs.

Increased Turbo Lag

Sticky vanes delay boost delivery. Turbo lag becomes more noticeable. The truck takes longer to build power after pressing the gas pedal. This makes driving less smooth and more frustrating.

Excessive Smoke From Exhaust

Carbon buildup can cause turbo seals to wear out. Oil leaks past these seals into the exhaust. This creates blue or white smoke from the tailpipe. Smoke means the turbo is burning oil, a sign of damage.

Loud Whining Or Whistling Noises

Blocked vanes cause uneven airflow inside the turbo. This produces unusual noises like whining or whistling. These sounds often increase with engine speed or when letting off the throttle.

Sticking Vanes Problems

The 6.7 Powerstroke turbo uses variable geometry turbo (VGT) technology. This means the turbo has vanes that move to control boost pressure. When these vanes stick, the turbo cannot adjust properly. Sticking vanes cause poor engine performance and other issues.

Carbon and soot build up inside the turbo housing. This buildup restricts the vanes from moving freely. As a result, the turbo either overboosts or underboosts. The engine feels sluggish and less powerful.

Symptoms Of Sticking Vanes

One common sign is slow acceleration. The truck struggles under heavy load or when climbing hills. You may hear a strange whining or whistling noise from the turbo area. Another sign is excessive black or blue smoke from the exhaust. This happens because the turbo cannot supply the right amount of air. Fuel burns improperly, causing smoke and poor fuel economy.

Causes Of Sticking Vanes

Carbon deposits form on the vanes due to incomplete combustion. Oil leaks inside the turbo can worsen the problem. Dirt and soot mix with oil, creating a sticky residue. This residue locks the vanes in place. Lack of regular maintenance speeds up carbon buildup and vane sticking.

Effects On Engine Performance

Sticking vanes reduce boost pressure control. The engine may lose power and feel weak. Fuel consumption rises as the engine works harder. The truck may stall or hesitate during acceleration. The check engine light often comes on. Turbo damage can lead to costly repairs if not addressed quickly.

Damaged Turbo Seals

Damaged turbo seals in a 6.7 Powerstroke often cause serious engine problems. These seals keep oil and air separated inside the turbo. When they fail, oil leaks into the intake or exhaust systems. This leads to poor engine performance and increased emissions.

Oil leaking past turbo seals can cause visible smoke from the exhaust pipe. The smoke may be blue or white, signaling oil burning in the engine. This condition reduces power and makes the engine run rough.

Symptoms Of Damaged Turbo Seals

Damaged seals cause noticeable power loss during acceleration. The engine may feel weak or sluggish under load. You might also hear unusual noises like whining or grinding from the turbo area. Excessive smoke coming from the exhaust is a common sign. Oil leaks around the turbo housing are often visible too.

Why Turbo Seals Fail

Turbo seals fail due to wear and tear or poor maintenance. Dirt and carbon buildup can damage the seals over time. High engine temperatures also cause the seals to degrade. Using low-quality oil or neglecting oil changes speeds up seal damage.

Fixing And Preventing Seal Damage

Repairing damaged turbo seals usually requires a turbo rebuild or replacement. Regular oil changes with the right oil type help prevent seal failure. Keeping the air filter clean reduces dirt entering the turbo. Early diagnosis can save your engine from costly repairs.

Reading Diagnostic Codes

Reading diagnostic codes is a key step in spotting a bad turbo on a 6.7 Powerstroke. These codes help identify specific issues inside the engine system. They tell you what part might be failing or acting up. Using a scanner tool, you can quickly access these error codes from the truck’s computer.

Diagnostic codes offer clear clues about turbo health. They cut down guesswork and save time. Knowing the codes can help you decide if the turbo needs repair or replacement. This approach protects your engine from further damage.

How To Access Diagnostic Codes

To read codes, use an OBD-II scanner suited for diesel trucks. Plug it into the truck’s port, usually under the dashboard. Turn on the ignition and run a scan. The tool will show any stored trouble codes.

Many scanners link to smartphones or tablets. This makes reading and understanding codes easier. Some apps explain what each code means in simple terms.

Common Turbo-related Diagnostic Codes

Look for codes like P0299, indicating low turbo boost pressure. Code P0234 means overboost, showing the turbo creates too much pressure. Codes P2263 and P2264 relate to the turbo’s variable geometry turbo (VGT) system. These codes often point to stuck vanes or actuator problems.

Finding these codes means the turbo needs attention. It helps target the exact cause of poor performance or smoke issues.

Using Codes To Plan Repairs

Once you have the codes, check the truck’s manual or online resources. They explain what fixes match each code. Some problems need simple cleaning or actuator adjustments.

Other issues may require turbo replacement. Sharing these codes with a mechanic speeds up diagnosis. You avoid costly trial and error repairs.

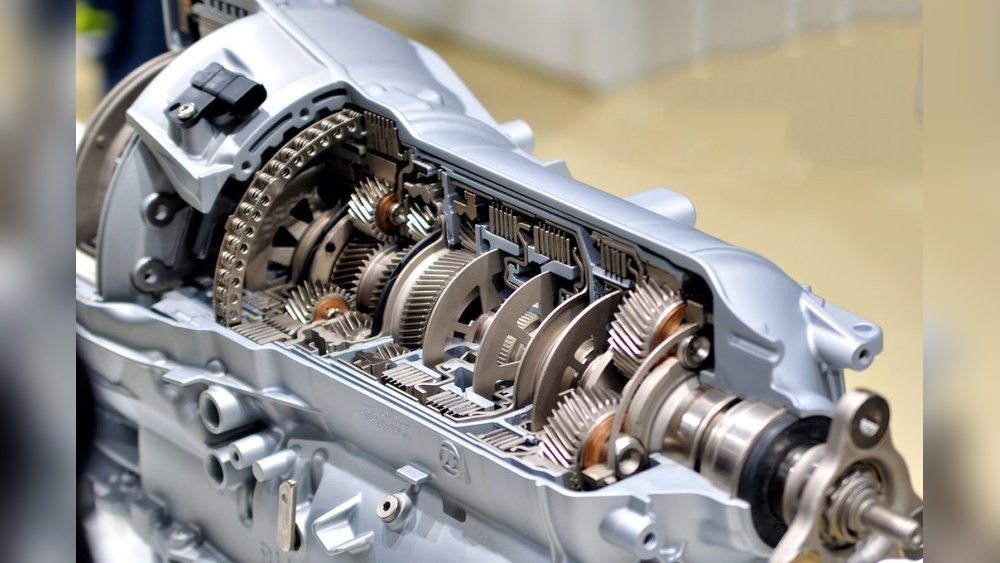

Professional Turbo Inspections

Professional turbo inspections play a key role in identifying issues early. A bad turbo on a 6.7 Powerstroke can cause many problems. Expert mechanics use special tools to check the turbo’s health. They look beyond simple symptoms to find hidden damage.

During an inspection, the mechanic examines the turbo’s internal parts. They check for worn bearings, cracks, and carbon buildup. These checks ensure the turbo works smoothly and efficiently. Finding issues early saves money and prevents breakdowns.

Visual Examination Of Turbo Components

The first step is a detailed visual check. Mechanics inspect the turbine and compressor wheels for damage. Cracks, chips, or excessive wear signal trouble. They also check for oil leaks around the turbo housing. Oil leaks can indicate failing seals or bearings.

Testing Turbo Boost Pressure

Measuring boost pressure reveals how well the turbo performs. Low boost pressure means the turbo may not supply enough air. This reduces engine power and increases smoke. Professionals use boost gauges to get accurate readings. They compare results to manufacturer specifications.

Checking Turbo Shaft Play

Turbo shaft play tests check the tightness of the turbo shaft. Too much play means worn bearings or shaft damage. Mechanics gently move the shaft side to side and in and out. Excessive movement means the turbo needs repair or replacement. This test prevents sudden turbo failure on the road.

Inspecting The Variable Geometry Turbo (vgt) Actuator

The VGT actuator controls the turbo’s vanes to adjust boost. Carbon buildup or sticking vanes cause poor turbo response. Professionals check the actuator’s movement and function. They clean or replace parts as needed. Proper VGT function improves engine performance and fuel economy.

Credit: boostedperformance.com

Preventative Maintenance Tips

Preventative maintenance plays a key role in keeping your 6.7 Powerstroke turbo in good shape. Regular care helps avoid costly repairs and extends turbo life. Simple steps can reduce wear and catch problems early. Follow these tips to maintain turbo efficiency and power.

Regular Oil Changes

Change engine oil on time using the right grade. Clean oil lubricates turbo bearings and prevents damage. Dirty or old oil causes buildup and wears parts fast. Stick to the manufacturer’s oil change schedule. This keeps the turbo running smoothly and avoids costly failures.

Clean Air Filters

Replace or clean air filters often to keep dirt out. Dust and debris can harm turbo blades and reduce airflow. A clean filter protects the turbo and improves engine performance. Check filters during routine service and swap them if clogged or dirty. This simple action helps maintain boost pressure and power.

Using High-quality Fuel

Choose fuel with good cetane rating and low impurities. Poor fuel can cause deposits and harm turbo parts. High-quality diesel burns cleaner and protects the engine. Avoid cheap or contaminated fuel sources. Using better fuel reduces carbon buildup and keeps the turbo operating efficiently.

Credit: www.powerstroke.org

Conclusion

A bad turbo on a 6. 7 Powerstroke shows clear warning signs. Watch for loss of power and slow acceleration. Excessive smoke often means oil or fuel problems. Strange noises like whining or grinding should not be ignored. Poor fuel economy signals the engine is struggling.

Oil leaks near the turbo need quick attention. Early action can save costly repairs later. Stay alert to these signs to keep your truck running strong. Regular checks and maintenance help avoid turbo trouble. Don’t wait until problems get worse—act as soon as you notice symptoms.