Have you ever wondered what goes into making the tires that carry you safely on every road? Tires might seem simple at first glance, but there’s a fascinating mix of materials working together beneath your feet.

Understanding what tires are made of can help you appreciate how they perform, last longer, and keep you safe. Whether you’re curious about the rubber, steel, or other components, this guide breaks it all down in a clear and easy way.

Stick with me, and you’ll see your tires in a whole new light—giving you the confidence to make smarter choices for your vehicle and your safety. Let’s dive into what really makes your tires roll.

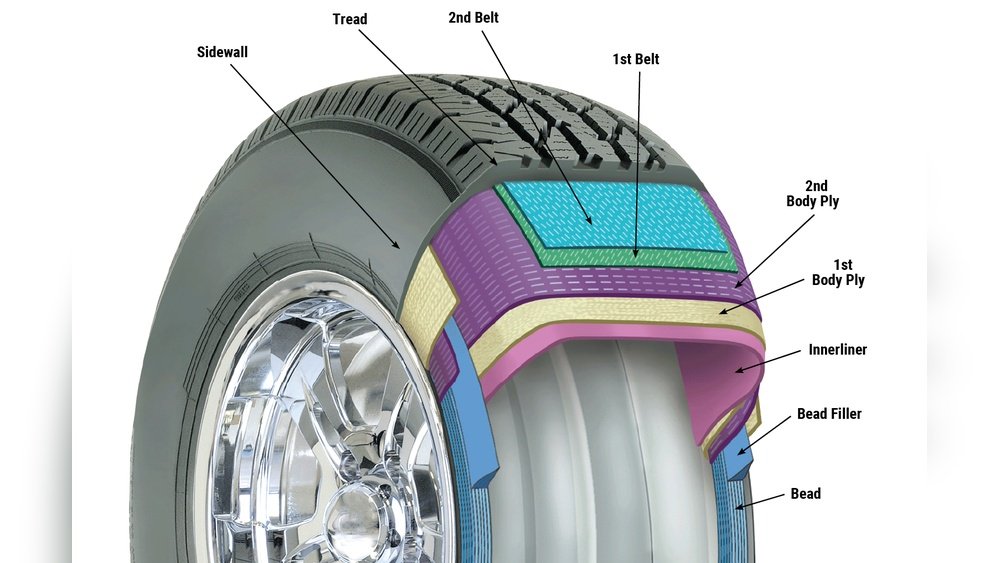

Tire Components

Tires consist of several important components. Each part plays a key role in performance, safety, and durability. Understanding these materials helps appreciate how tires handle roads and weather.

These components work together to provide strength, flexibility, and grip. The mix of materials varies by tire type and use. Below are the main ingredients found in most tires.

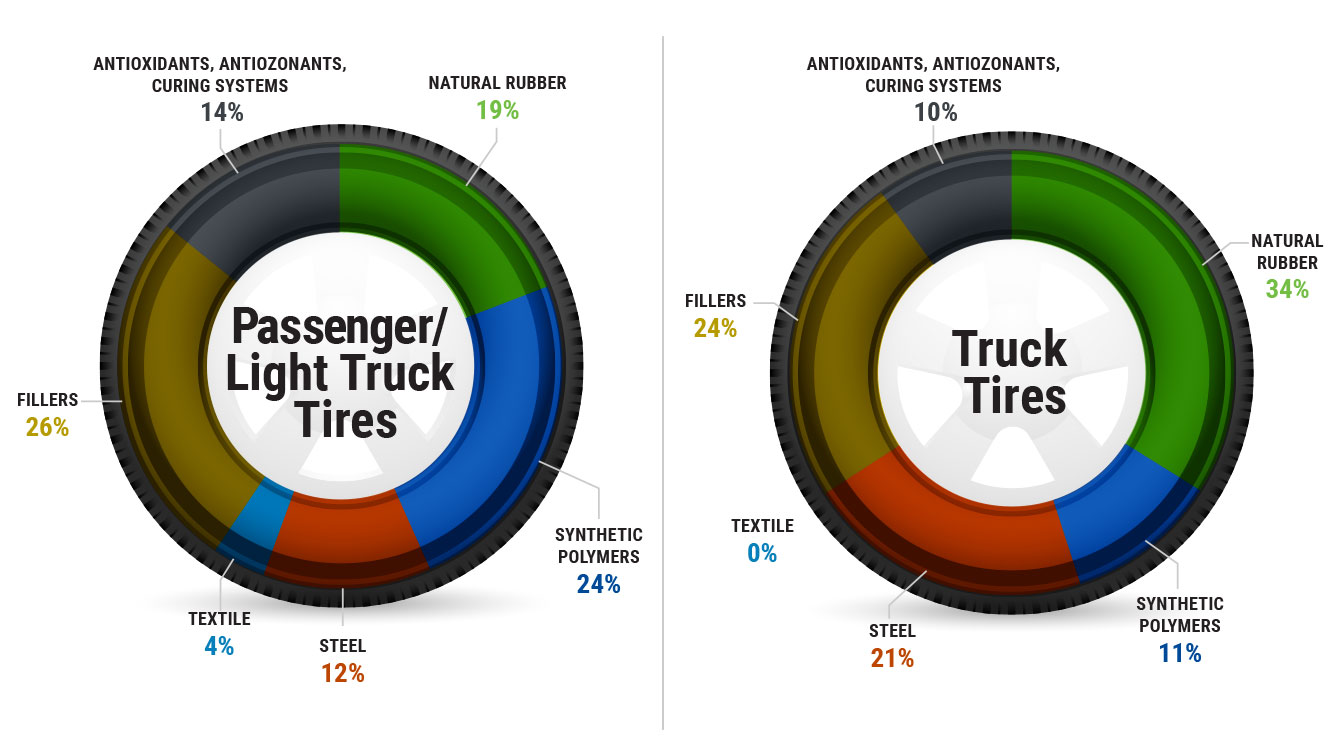

Natural Rubber

Natural rubber comes from rubber trees. It gives tires flexibility and resilience. This material helps tires stay soft in cold weather. It also improves traction on wet surfaces.

Synthetic Rubber

Synthetic rubber is made from chemicals in factories. It offers strength and resistance to heat. Tires use it to handle high speeds and rough roads. It also lasts longer than natural rubber alone.

Steel And Fabric

Steel wires form the tire’s belts and beads. These parts add strength and shape. Fabric layers, often made of polyester or nylon, provide flexibility. Together, they keep the tire stable and durable.

Carbon Black And Silica

Carbon black is a fine black powder added to rubber. It makes tires stronger and protects from UV damage. Silica improves grip and reduces rolling resistance. Both materials increase tire life and fuel efficiency.

Natural Rubber Sources

Natural rubber is a key material used in making tires. It comes from certain trees that produce a sticky, milky fluid called latex. This latex is collected and processed to create the rubber needed for tire production. The quality and source of natural rubber affect the tire’s strength, flexibility, and durability.

Hevea Brasiliensis Trees

The primary source of natural rubber is the Hevea brasiliensis tree. These trees grow mainly in tropical regions such as Southeast Asia and parts of Africa. They produce latex in their bark, which looks like white sap. Farmers make small cuts in the bark to collect the latex without harming the tree. This process is called tapping.

Hevea brasiliensis trees can produce latex for many years. They are carefully cultivated to ensure a steady supply. This natural rubber is preferred for tires because it offers excellent elasticity and resilience. It helps tires grip roads and absorb shocks better than synthetic alternatives.

Sustainable Harvesting

Sustainable harvesting protects the environment and the trees. Farmers follow practices that allow the trees to heal between latex collections. This prevents damage and keeps the trees healthy for longer use. Sustainable methods also reduce deforestation and support local communities.

Many rubber plantations now use eco-friendly techniques. These include limiting chemical use and preserving forest areas around the plantations. Sustainable harvesting ensures a continuous supply of natural rubber without harming the planet. It also helps maintain biodiversity in rubber-growing regions.

Synthetic Rubber Varieties

Synthetic rubber plays a key role in making modern tires durable and safe. It offers properties that natural rubber alone cannot provide. Different types of synthetic rubbers are mixed to improve tire performance under various conditions. These rubbers help tires resist heat, wear, and damage from rough roads. Understanding the main synthetic rubber varieties reveals how tires stay strong and reliable.

Butadiene Rubber

Butadiene rubber is a common synthetic rubber used in tires. It offers excellent resistance to wear and tear. This rubber type improves the tire’s toughness and flexibility. It also performs well in cold weather without becoming too hard. Tires with butadiene rubber last longer on rough surfaces. Its strong resistance to abrasion makes it ideal for tread areas.

Styrene-butadiene Rubber

Styrene-butadiene rubber, often called SBR, is another widely used synthetic rubber. It combines the strength of styrene with the flexibility of butadiene. This blend creates tires that grip roads better and resist damage. SBR enhances tire durability and heat resistance. It also helps reduce rolling resistance for better fuel efficiency. Most passenger car tires contain a significant amount of SBR.

Credit: mechse.illinois.edu

Reinforcing Materials

Tires need strong materials inside to stay safe and last long. Reinforcing materials help tires handle pressure and rough roads. They keep the tire shape and stop it from breaking.

These materials work with rubber to give the tire strength and flexibility. They help the tire grip the road and carry heavy loads. Two main types of reinforcing materials are steel belts and textile plies.

Steel Belts

Steel belts are thin strips of steel wires. They lie under the tread of the tire. These belts make the tire stronger and more durable.

Steel belts help the tire resist punctures and cuts. They keep the tread flat on the road, which improves grip and safety. Steel belts also reduce tire wear, making tires last longer.

Textile Plies

Textile plies are layers of fabric inside the tire. These fabrics use materials like polyester, nylon, or rayon. They add flexibility and strength to the tire body.

Textile plies help the tire keep its shape during movement. They absorb shocks from bumps and rough surfaces. This makes the ride smoother and protects the tire from damage.

Fillers And Additives

Tires are more than just rubber and air. They contain special materials called fillers and additives. These ingredients improve strength, durability, and performance. They help tires resist wear, heat, and damage. Below, learn about key fillers and additives that make tires better.

Carbon Black Role

Carbon black is a black powder added to tire rubber. It makes tires stronger and more durable. This filler helps tires resist wear from the road. It also protects tires from damage caused by sunlight and heat. Carbon black improves tire grip, making driving safer. Without it, tires would wear out quickly and crack.

Silica Benefits

Silica is another common filler in tires. It helps reduce rolling resistance, which saves fuel. Tires with silica also perform better on wet roads. This additive improves grip and safety in rainy conditions. Silica makes tires more flexible in cold weather. It helps tires last longer by reducing heat build-up.

Antioxidants And Anti-ozone Agents

Antioxidants protect tires from damage by oxygen and heat. They keep rubber from breaking down over time. Anti-ozone agents stop cracks caused by ozone in the air. These additives extend the life of tires. They help tires stay strong and flexible in harsh environments. Without them, tires would age faster and fail sooner.

Credit: www.sullivantire.com

Tire Manufacturing Process

The tire manufacturing process transforms raw materials into durable, road-ready tires. It involves several key steps to ensure quality and performance. Each step requires precision and care to create tires that meet safety standards and last long on the road.

Mixing Raw Materials

The process begins by mixing raw materials like natural rubber, synthetic rubber, carbon black, and chemicals. These ingredients blend in giant mixers to form a uniform rubber compound. This mixture provides strength, flexibility, and resistance to wear.

Building The Tire

Next, the rubber compound moves to the tire-building stage. Layers of fabric and steel belts are added to reinforce the structure. Machines shape these layers on a drum, forming the tire’s body and tread pattern. This step creates the tire’s basic shape and strength.

Vulcanization

Finally, vulcanization heats the tire in a mold under pressure. This process hardens the rubber and bonds all parts together. The heat also imprints the tread design on the tire’s surface. Vulcanization gives tires their final durability and elasticity.

Innovative And Surprising Materials

Tire makers use new and unusual materials to improve tires. These materials help tires last longer and perform better. Some come from nature, others from recycling or science. This section explores the innovative and surprising materials used in tires today.

Recycled Rubber

Recycled rubber comes from old tires and scrap rubber. It lowers waste and helps the environment. Tire makers mix recycled rubber with new rubber. This keeps tires strong and flexible. Using recycled rubber cuts costs and saves resources.

Bio-based Polymers

Bio-based polymers come from plants like corn or sugarcane. They replace some chemicals made from oil. These polymers reduce the tire’s carbon footprint. Tires with bio-based polymers still perform well. They help create greener, more eco-friendly tires.

Nanomaterials In Tires

Nanomaterials are tiny particles added to tire rubber. They make tires tougher and more durable. Nanomaterials improve grip on wet or slippery roads. They also help tires wear more evenly. This technology extends tire life and boosts safety.

Credit: www.ustires.org

Environmental Impact

Tires have a significant environmental impact due to the materials used and the processes involved. Manufacturing tires requires natural and synthetic rubber, chemicals, and metals. These materials often come from sources that affect ecosystems and communities. Waste from tire production and disposal also creates pollution and landfill challenges.

Understanding this impact helps us think about better ways to reduce harm. Exploring how tires are sourced, recycled, and replaced with greener options gives insight into making choices that protect the planet.

Sourcing Challenges

Natural rubber comes mainly from rubber trees in tropical regions. Growing these trees can lead to deforestation and loss of wildlife habitats. Synthetic rubber is made from petroleum, a non-renewable resource. Extracting and refining petroleum causes pollution and greenhouse gas emissions.

Many chemicals in tires also come from mining or industrial processes. These can pollute air and water near factories. Transportation of raw materials adds to carbon emissions. Overall, sourcing tire ingredients strains natural resources and ecosystems.

Recycling And Reuse

Tire recycling helps reduce waste and conserve resources. Old tires can be shredded and used in road construction, playground surfaces, and new products. Recycling saves space in landfills and lowers pollution risks.

Not all tires get recycled properly. Some end up in dumps or are burned, releasing toxic fumes. Improving recycling systems and public awareness is key. Reusing tire materials extends their life and cuts demand for new resources.

Sustainable Alternatives

Researchers work on greener tire materials to lower environmental harm. Some companies use bio-based rubbers from plants like dandelions or guayule. These sources grow faster and need less land than rubber trees.

Other alternatives include recycled rubber blends and eco-friendly chemicals. Designing tires for longer life and easier recycling also helps. Supporting sustainable tire options reduces pollution and resource use.

Nitrogen Vs. Air In Tires

Choosing between nitrogen and regular air for your tires affects tire performance and maintenance. Both gases fill tires, but they behave differently inside the tire. Understanding these differences helps you decide the best option for your vehicle.

Benefits Of Nitrogen

Nitrogen molecules are larger than oxygen molecules. This size difference means nitrogen leaks out of tires more slowly. Tires filled with nitrogen keep pressure longer than air-filled tires. Stable pressure improves tire life and fuel efficiency. Nitrogen also reacts less to temperature changes. This means tire pressure stays more constant in hot or cold weather. Nitrogen does not support moisture inside tires, reducing corrosion risk on rims and tire components.

Mixing Air And Nitrogen

It is safe to mix air and nitrogen inside a tire. Adding regular air to a nitrogen-filled tire will dilute the nitrogen. This reduces the benefits of pure nitrogen fill. The tire still works fine, but pressure stability may decrease. If you need to top off tire pressure and nitrogen is unavailable, adding air is acceptable. Over time, the mixture will behave more like regular air.

Safety Considerations

Both nitrogen and air are safe for tire inflation. Mixing the two gases does not create harmful reactions. Maintaining correct tire pressure is more important than the gas type. Low tire pressure causes poor handling and higher fuel use. Check tire pressure regularly regardless of the gas used. Use nitrogen if you want longer pressure retention and less moisture inside the tire.

Frequently Asked Questions

Are Tires Still Made From Trees?

Tires still use natural rubber from rubber trees but combine it with synthetic materials for durability and performance.

Can You Put Air In Nitrogen-filled Tires?

Yes, you can add regular air to nitrogen-filled tires safely. It dilutes nitrogen, reducing pressure stability benefits but won’t harm tires.

Why Are Tires Not All Rubber?

Tires combine rubber with fabric, steel, and chemicals for strength, durability, and performance. Pure rubber lacks necessary toughness and grip.

Are Tires Made From Petroleum?

Yes, tires contain petroleum-based synthetic rubber and other materials. Petroleum provides durability, flexibility, and resistance needed for tire performance.

Conclusion

Tires combine natural and synthetic rubber with other materials. Steel and fabric add strength and flexibility. Chemicals enhance durability and grip on the road. Understanding tire components helps you appreciate their design. Tires keep you safe and comfortable while driving.

Knowing what tires are made of aids smart choices. Always check your tires regularly for best performance. Quality tires protect you and improve your vehicle’s efficiency.